Add to Cart

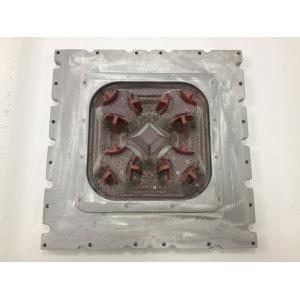

Pulp Mold, Cup Holder Mould, Tooling For Rotary Forming Machine, Mould Dies

Descriptions:

| Product Name | Cup Holder / Cup Carrier Mold, Mould |

| Category | Forming Mold, Mould, Tooling |

| Material | Plastic, Aluminum or Brass, depends on customer's budget |

| Usage | To Make Cup Holder Used Molded Pulp |

| Service | Customized Design, Internal Mold Test Prior To Shipment |

| Lead Time | Depends On Qty & Material to be used |

| Shipping Term | EXW |

| Paymen Term | TT In Advance |

| Packing | Wood Pallet |

3 tips for extending the lifespan of your mold:

1. Make sure the mold is installed correctly without crushing in between.

2. The forming mold must be washed well by high pressure water spray for every cycle to avoid net blockage.

3. After used for a period of time, if finished product found to be lack of pulp, means the net is blocked need to be washed deeply, if problem not be solved, is time to change mesh and clean up suction holes.

Why choose us:

WINNER PULP has actively participated in design and developing molds for packaging specialist using molded pulp to worldwide for more than two decades. Our in-house team is completely staffed by highly skilled craftsmen with a strong industry reputation. We use 3D scanner to measure the tools regularly which enables us to manufacture your parts with great precision no matter how simple or complex your part designs may be.

Finished Product: